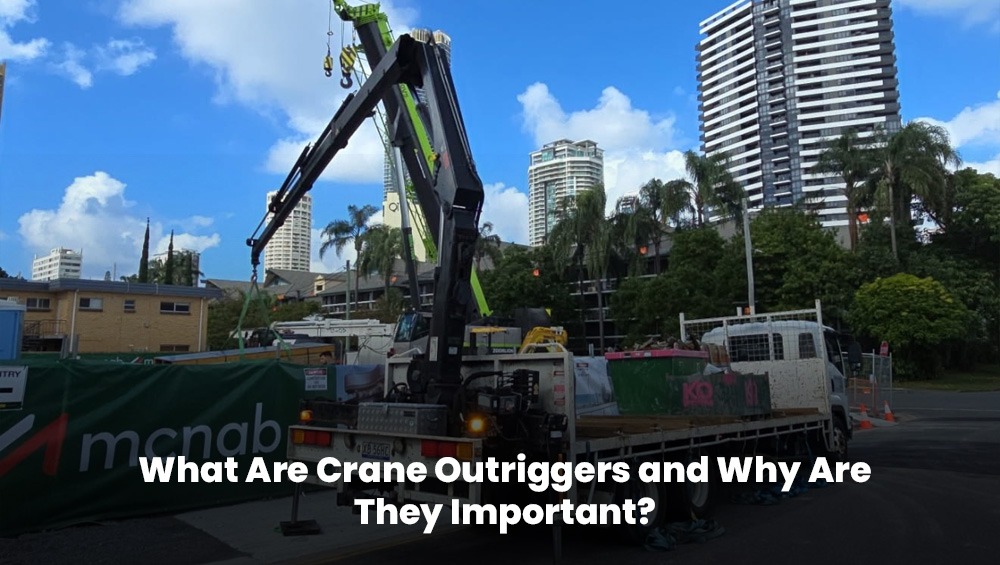

What Are Crane Outriggers and Why Are They Important?

Outriggers are one of the most important safety features on a crane, yet they’re often overlooked by clients and even some operators. Whether you’re lifting steel beams on a commercial high-rise or transporting prefab panels for a residential build, your crane is only as safe as the ground it stands on — and that’s exactly what outriggers are made to secure.

In this blog, we’re cutting through the usual technical language to explain exactly what outriggers do, why they matter, and when they’re non-negotiable — especially if you’re hiring a crane on the Gold Coast, where site conditions can vary dramatically.

What Are Crane Outriggers?

Crane outriggers are extendable horizontal and vertical supports that provide additional stability during crane operations. They counterbalance the crane’s weight and the load being lifted to prevent tipping or instability. Without outriggers, a crane’s lifting capacity would be significantly reduced and potentially unsafe in most field conditions.

Types of Cranes That Use Outriggers:

- All-Terrain Cranes: Designed for both road travel and off-road use; require outriggers for lifting operations.

- Truck-Mounted Cranes: Feature integrated outriggers that are deployed when lifting.

- Rough Terrain Cranes: Used on rugged sites, these cranes heavily rely on outriggers for balance.

Outriggers are not optional; they are a fundamental part of lifting safely and efficiently.

How Do Outriggers Work?

The function of outriggers is to provide leverage. As the based on physics crane begins a lift, especially at a distance from its centreline, tipping forces increase. Outriggers combat this by creating a wider base, redistributing forces, and keeping the crane balanced.

How They Operate:

- The crane is positioned on the job site.

- Outriggers are extended horizontally.

- Hydraulic legs lower vertically to lift the crane slightly off its wheels.

- Load-bearing mats or pads ensure the pressure is evenly dispersed.

This setup allows:

- Full utilization of crane load charts

- Enhanced lifting capacity

- Elimination of tyre compression, increasing overall safety

Why Are Outriggers Important for Crane Safety?

When it comes to lifting heavy loads, stability isn’t optional — it’s essential. That’s exactly where outriggers come in. Here’s why they play a critical role in crane safety:

1. They Keep the Crane Balanced During Lifts

Outriggers extend outward from the crane, creating a wider and more stable base. This stops the crane from leaning or shifting, especially when the boom is fully extended or lifting at an angle. Simply put — no outriggers, no safe lift.

2. They Help Prevent Crane Tip-Overs

A crane without proper support is at risk of tipping, especially under heavy or uneven loads. Outriggers redistribute the weight and stop the crane from losing balance. It’s one of the simplest and most effective ways to prevent dangerous accidents on-site.

3. They’re a Must on Soft or Uneven Ground

Not every job site has solid, level ground. Whether it’s sand, gravel, or sloped terrain, outriggers help stabilise the crane by lifting it slightly off the wheels and spreading the pressure. That makes a huge difference in safety when the surface underneath isn’t reliable.

4. They Protect Everyone and Everything Around the Crane

A stable crane is a safe crane. Outriggers reduce the chance of sudden movement or collapse, helping protect workers, nearby structures, and expensive equipment. They’re a small part of the crane, but a big part of jobsite safety.

Outriggers vs. Cranes Without Outriggers

Not all cranes are designed with outriggers. A perfect example is the Franna crane, which is a mobile pick-and-carry crane without outriggers. It relies on its counterweights and compact design to lift and carry loads over short distances.

Cranes with outriggers:

- Provide better stability

- Are ideal for stationary, heavy, or high-risk lifts

- Require setup time to deploy outriggers

Franna cranes (without outriggers):

- Offer mobility and quick setup

- Ideal for small or indoor lifts

- Limited in lifting capacity and stability compared to larger cranes with outriggers

When Should You Use a Crane with Outriggers?

While every lift has unique requirements, there are common situations where a crane with outriggers is essential:

- High-risk lifts involving large, heavy, or awkward loads

- Rough or uneven terrain, such as sloped job sites or muddy areas

- Urban sites with limited space, where stability is critical

- Tall lifts that increase the tipping risk due to leverage

In short, if safety, precision, and heavy lifting are required, outriggers are non-negotiable.

HNH Crane’s Commitment to Safe Lifting on the Gold Coast

At HNH Crane, we understand that your project depends on both efficiency and safety. That’s why our Crane Hire Gold Coast includes a fleet of cranes equipped with modern outrigger systems.

Here’s what sets us apart:

- Experienced Operators: Our licensed crane operators and riggers are trained to safely set up and manage outriggers for all lift types.

- Site Inspections: We assess site conditions before each lift to determine the right equipment, outrigger positioning, and ground prep.

- Versatile Fleet: Whether your job needs an all-terrain crane with hydraulic outriggers, we’ve got it covered.

- Focus on Safety Compliance: We strictly follow Australian lifting standards and safety codes.

When it comes to lifting anything of value — materials, time, or trust — outriggers are the silent backbone of every safe lift. They’re not flashy, but they do the heavy lifting when it comes to safety and stability.

If you’re investing in a crane hire service, you’re not just paying for the machine. You’re investing in experience, planning, and the safety systems that come with it. Outriggers are a key part of that package.

At HNH Crane, every lift is calculated, stabilised, and executed with the right equipment — including outriggers when required. We don’t take shortcuts because when you’re lifting 10 tonnes of concrete, shortcuts aren’t an option.

FAQ

1. How does the use of outriggers increase the tipping capacity of a crane?

Outriggers increase a crane’s tipping capacity by widening its base and evenly distributing load weight, enhancing overall stability during lifts.

2. Can outriggers be used on sloped surfaces?

Yes, with proper levelling and ground preparation, outriggers can be safely deployed on mild slopes.

3. Is it possible to hire a crane for just a few hours?

Many providers offer flexible short-term hire options.

4. Are your crane operators licensed and experienced?

Yes, all our crane operators are fully licensed and certified to operate under Australian safety standards.

5. How do I know what size crane I need?

Simply contact our team. We’ll assess your lifting requirements and recommend the most suitable crane for safety and efficiency.